Date Posted: 04.26.2022

Humans have an innate need to connect with the natural world. This relationship is critically important in the built environments where children learn. At the same time, emerging mass timber technology has the capacity to help reduce and achieve net-negative embodied carbon. Finding a way to optimize mass timber technology that affords a cost-competitive biophilic approach to build better schools is the missing link.

Grounded with a collection of precedent research and developed in collaboration with Bayley Construction and PCS Structural Engineers, Mithun R+D project Building Better Schools presents a mass timber framework for learning environments that maximizes the physiological and psychological benefits of natural materials within the cost structure of typical school budgets.

THE HUMAN FACTOR: BIOPHILIA

The fundamental elementary school design problem asks: What environment optimizes cognitive function (learning, memory, emotion, communication, and social intelligence) in a developing child? Neuroscientists are hard at work studying the functions and dynamics of the human brain, and a better understanding of how the brain modulates our immune system’s reaction by responding to environmental attributes and patterns we perceive around our body is beginning to emerge. This new insight is demonstrating the effectiveness of natural attributes in interior environments, known as biophilia, and how a perceived connection to natural surroundings plays a pivotal role in reducing stress and enhancing the ability to focus and sustain attention—critical aspects of improving cognitive function.

And so, the Building Better Schools design team asked: Can biophilic design through integration of mass timber in learning environments have a positive effect on the successful education of our children?

On average, children spend seven hours in school per day—that’s 1,260 hours per year and 15,120 total hours in grades K-12—and an average of 90% of time spent indoors. So, it’s important to get the indoor climate right. This means looking at everything from air quality, hygiene, humidity and temperature to the touch and feel of the materials that surround us. These aspects affect us in our day-to-day indoor lives. Wood as a building material is also an important part of biophilic design. Increasing evidence shows that wood has benefits that help reduce stress, blood pressure and heart rate as well as allow for more creativity and productivity. Incorporating natural elements into the built environment, where people spend most of their time, contributes to overall human wellbeing.

Children with access to nature exhibit lower levels of stress than those without; children in daylit classrooms have test scores 7-18% higher while children without daylight saw test scores drop by 17%. Similarly, exposure to wood in indoor environments invokes positive biophilic responses. Many people feel innately better in an interior wood environment—associating wood with nature, warmth, and health—and maintain a preference for wood versus other materials. Research shows wood surfaces reduce activation of the sympathetic nervous system, helping to calm the body before the onset of stress.

Students in the naturally daylit library at Blakely Elementary School.

ENVIRONMENTAL BENEFITS

Carbon emissions are recognized as the leading cause of climate change and buildings are responsible for 39% of that globally. Eleven percent of that is comprised of embodied carbon from material extraction and construction. Science is demonstrating that substituting wood for steel and concrete in construction can substantially reduce total carbon output and reduce existing carbon in the atmosphere through carbon sequestration.

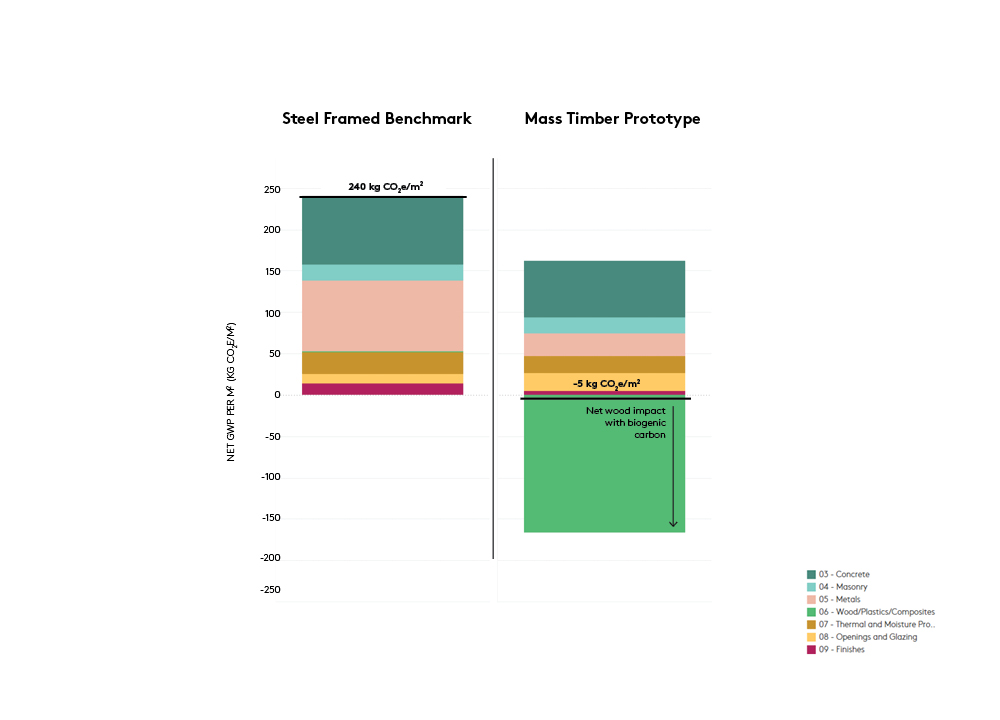

The Building Better Schools mass timber prototype reduces emissions from material manufacturing and production by about 30% compared to the steel-frame baseline. The carbon sequestered in the wood materials also results in a net negative embodied carbon footprint, meaning the building stores more carbon than is emitted incurred during material production. This represents a 102% reduction in embodied carbon compared to a steel framed baseline.

Carbon analysis comparing Steel Framed School benchmark to a mass timber prototype using three-ply CLT panels.

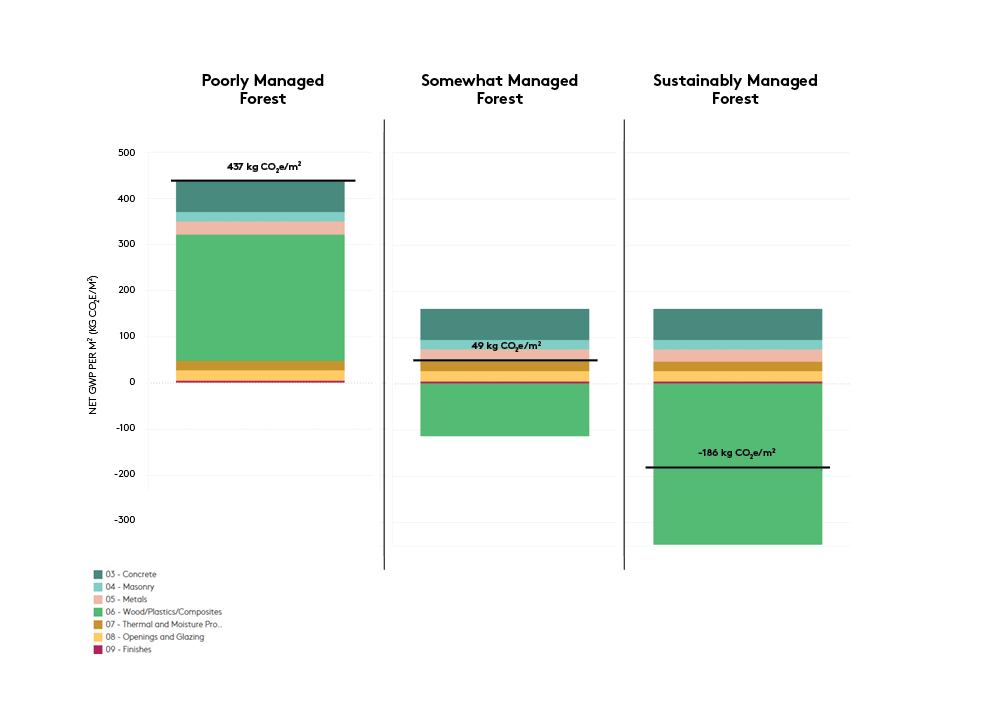

Sustainably managed forests are key to the Earth’s natural carbon capture and storage system—approximately, one cubic meter of wood stores one ton of carbon dioxide. As part of the photosynthesis process, trees take in carbon dioxide to create simple carbohydrates that can be used to nourish their existing cells or create new cells. In the lower 48 states alone, forests store more than 14 billion metric tons of CO2.

The forest cycle can be thought of having three phases: carbon capture, carbon storage and carbon release. In the first phase of the cycle, a tree grows and uses carbon dioxide absorbed from the atmosphere as its building blocks. In the second phase, the tree is mature and no longer uses as much carbon for growth. In the third phase, the tree releases more carbon than it captures as it declines in health and parts of the tree begin to decay. As the tree dies however, a portion of the carbon remains stored in the soil. By taking advantage of this natural cycle and harvesting young trees as part of well-managed forest production, carbon can be stored in durable, long-lived mass timber products that continue storing carbon while in service.

Total embodied carbon impact analysis based on various levels of forest management.

SCHOOL CONSTRUCTION BENEFITS

Because the large mass timber elements are fabricated offsite in a factory environment with extreme precision, the amount of time to construct mass timber projects is reduced significantly. Many studies have shown a reduction in construction schedule by approximately 25%. This savings is in part a result of the precise computer modeling of the structure, including careful machining of the mass timber connections and penetrations for mechanical, plumbing and electrical systems, allowing systems to erect efficiently on-site.

This new building approach also significantly cuts down on local disruptions associated with construction such as increased traffic, lane closures and noise. Smaller crews require fewer parking spaces, and truck deliveries are minimized. Connections are primarily done with special screw fasteners; thus, construction sites are eerily quiet. Because the building’s mass timber elements are premanufactured and show up using a “just-in-time” delivery method, there is very little wood waste or on-site storage required.

EDUCATIONAL AGILITY

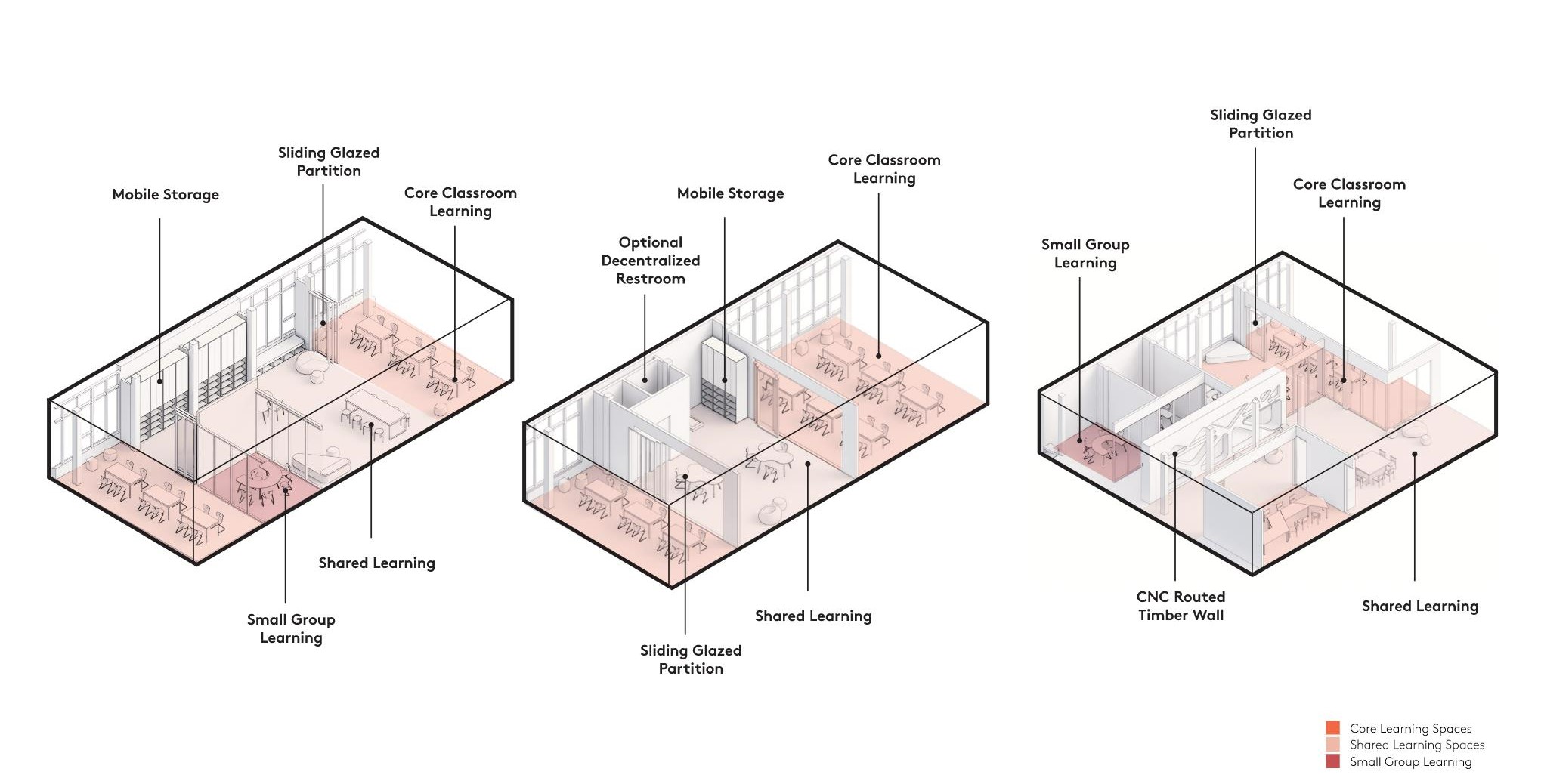

When learning environments are designed to align space with effective educational practices, both pedagogy and student success is amplified. Well-designed schools provide an agile framework for education that facilitates continued evolution in the practice of teaching and learning. Embracing construction with mass timber afforded the Building Better Schools R+D team a new lens through which a kit-of-parts approach emerged with the advantage of flexibility in configuration, resulting in endless customizable educational agility for school design.

Diagrams illustrating range of educational agility provided by the system.

THE KIT-OF-PARTS

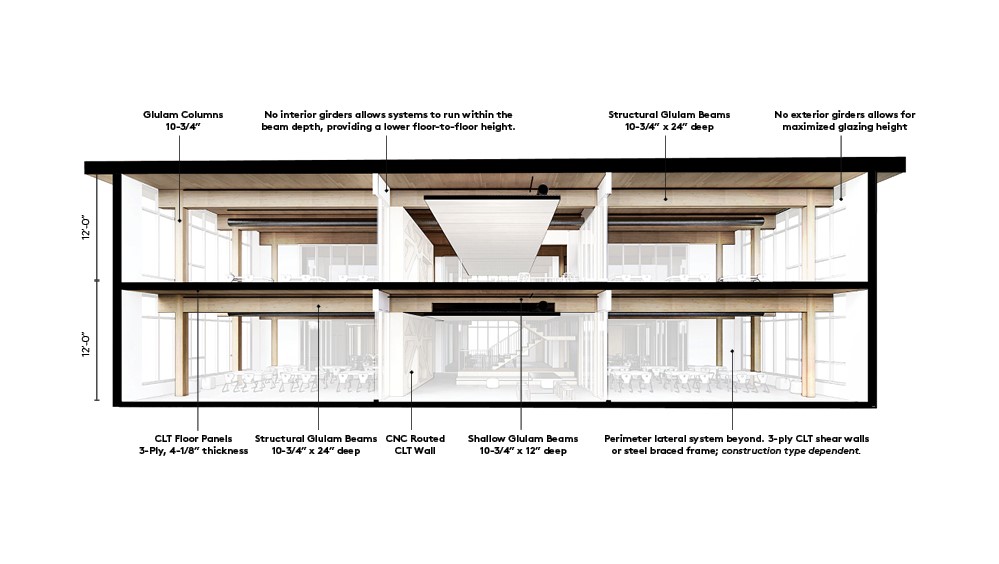

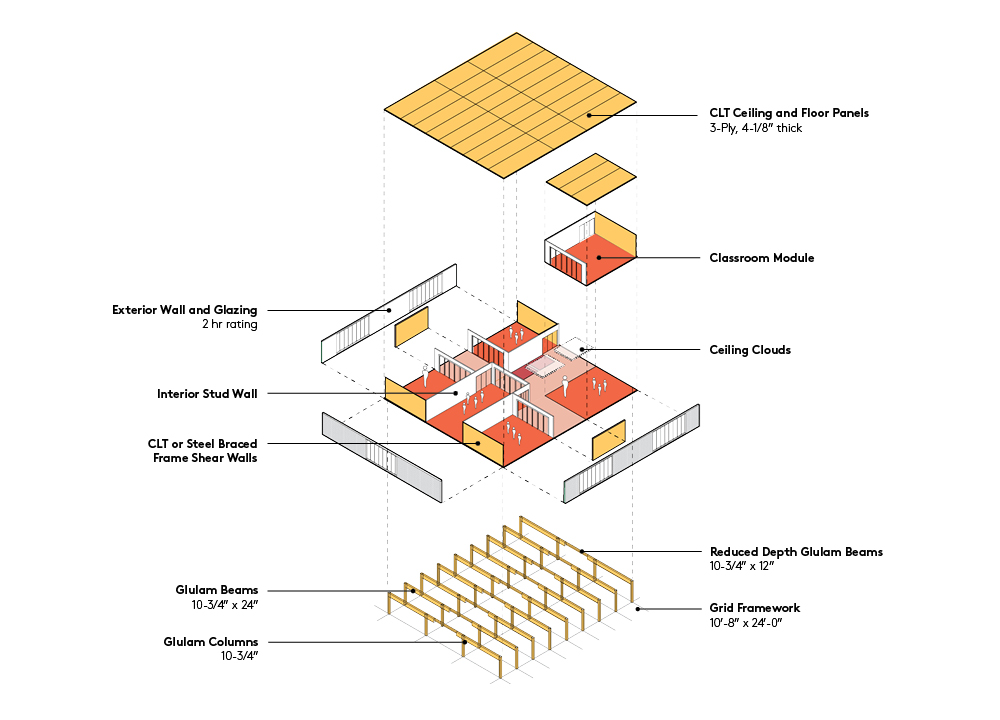

Mass timber performs most efficiently when designed to optimize spans that minimize wood fiber density. Through an iterative approach, the R+D team identified the need to maximize the use of three-ply panels to minimize cost and embodied carbon. And, if applied to a girder-less section and modular column grid, it was determined a kit-of-parts solution would provide maximum cost efficiency, programmatic adaptability and project customization.

Building section demonstrating efficiency of a girder-less system.

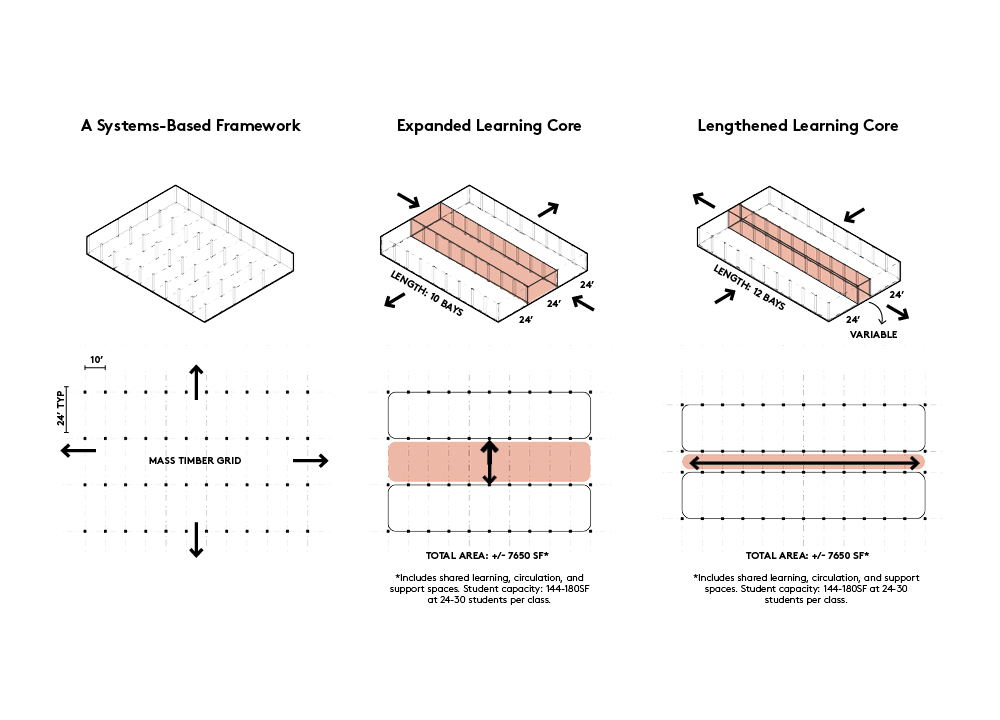

Able to adapt to each school’s individual site, pedagogy and design needs, the kit-of-parts approach establishes a framework derived from an optimized balance between minimal ply timber spans and classroom program, resulting in a short- or long-span structural framework.

Core learning areas are comprised of a series of elements that are adaptable to a range of educational pedagogies. Customization is further embedded into the structural framework through a ‘flexible’ learning core that lengthens or expands to achieve various collaborative environments while maintaining a comparable total learning area.

Diagram illustrating the structural mass timber framework with flexible core.

Metal stud and gypsum board walls support operable glazed interior partitions to allow for classroom expansion to shared learning and provide visual transparency to adjacent learning areas. Three-ply mass timber ceiling panels are left exposed where possible above learning areas, with ceiling clouds used strategically for acoustics or MEP integration. Depending on the building construction type, CLT shear walls can be implemented for the lateral system, but in instances where combustible material in the exterior wall is not permitted by code, steel braced frames are used.

Mass timber kit-of-parts diagram for core learning areas derived from the systems-based framework.

MASS TIMBER’S FUTURE

Moving from carbon-intensive steel and concrete buildings to structures built of mass timber is recognized as one of the few levers we have in the building industry to reduce the effects of climate change. This Mithun-sponsored research effort proves why it is especially attractive for K-12 educational programs. Importantly, it demonstrates that by working within the inherent design parameters of mass timber to minimize wood fiber, a three-ply CLT solution can minimize carbon, improve student learning outcomes, reduce construction time and site impacts, and be built within costs that are on par with more conventional structural systems.

The full research report is available for download here, including a complete listing of sources and research precedents for further exploration.