Detailing to Pass the NFPA 285

Vision

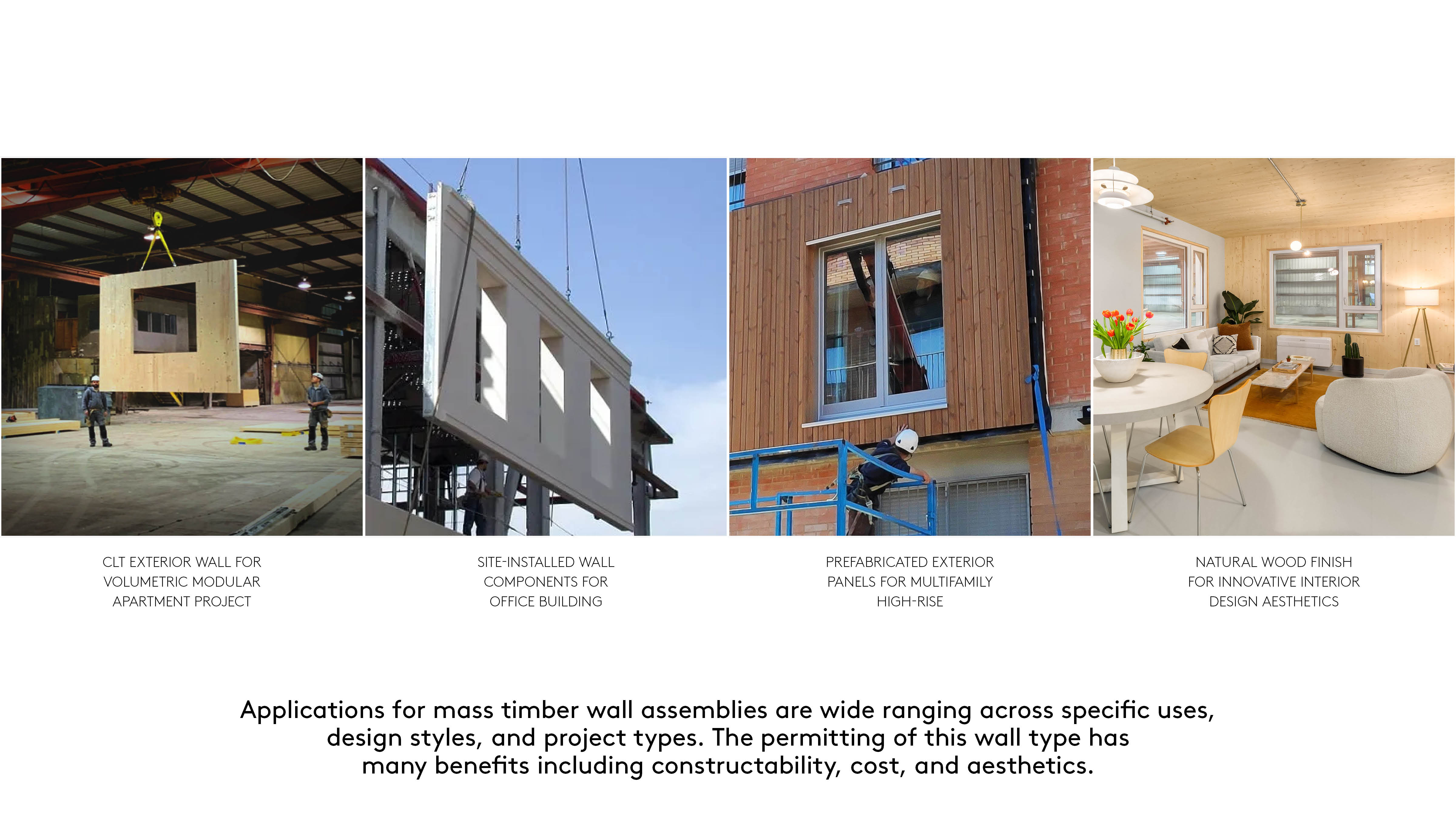

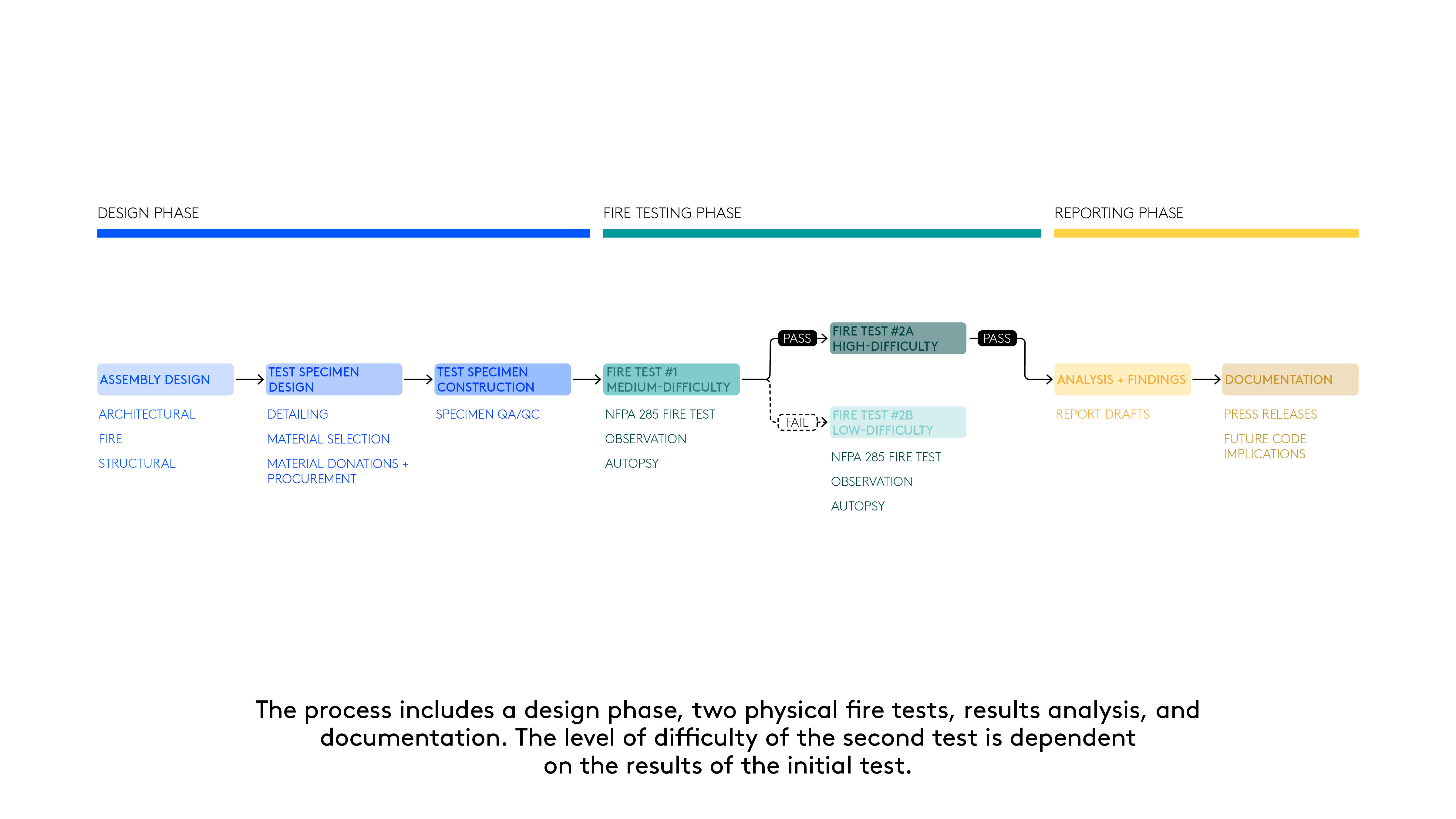

The goal for these fire tests was to create new opportunities for exterior wall and façade design and production in tall timber buildings. Mass timber is relatively new to North American construction, and most assemblies designed around wood at this scale are theoretically fire-resistant, but literally untested. Each fire test broadens the knowledge about how mass timber elements and other material components behave in fire, and each passed test adds to the library of code-compliant mass timber assemblies available to the general public.

Research

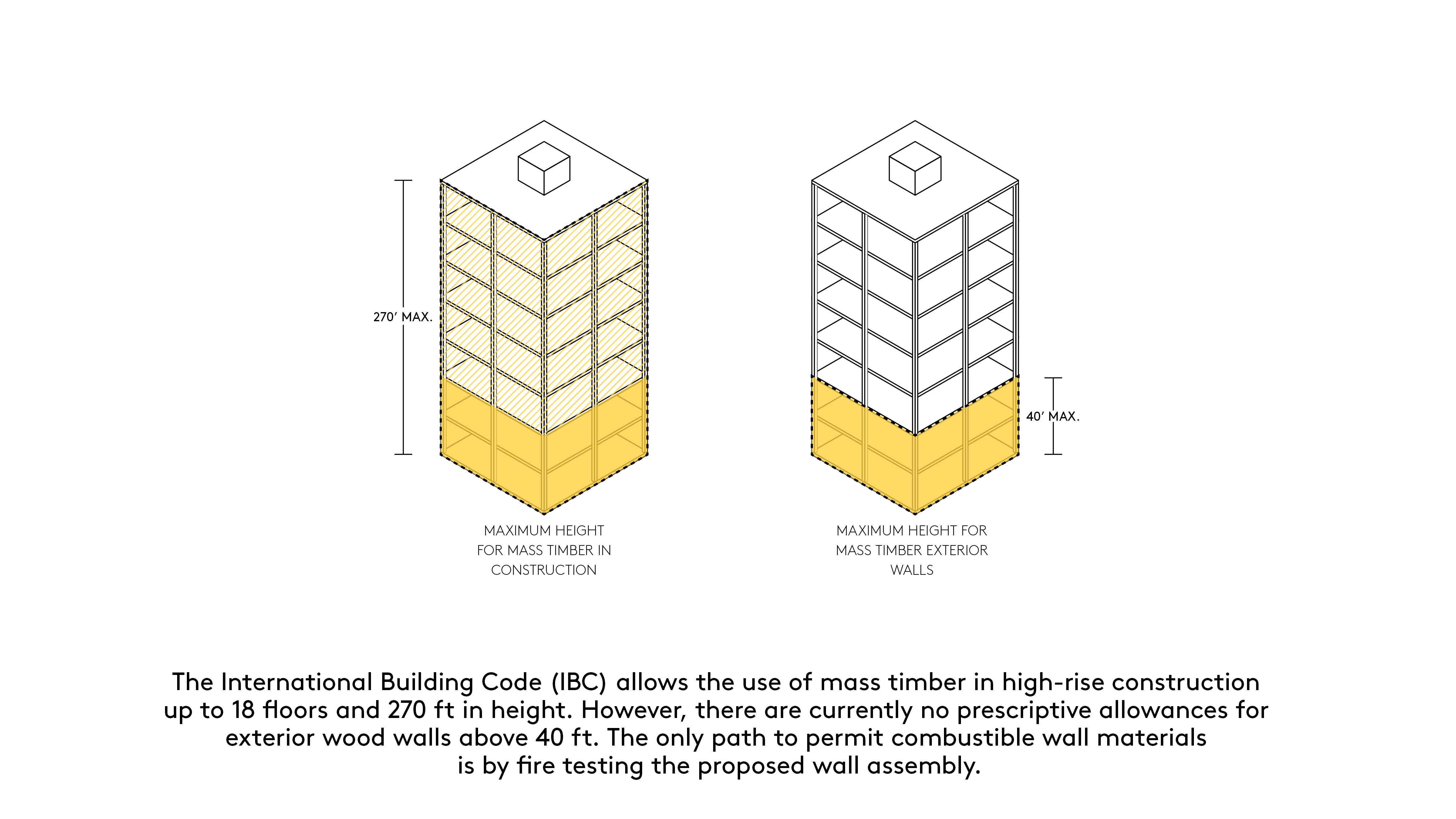

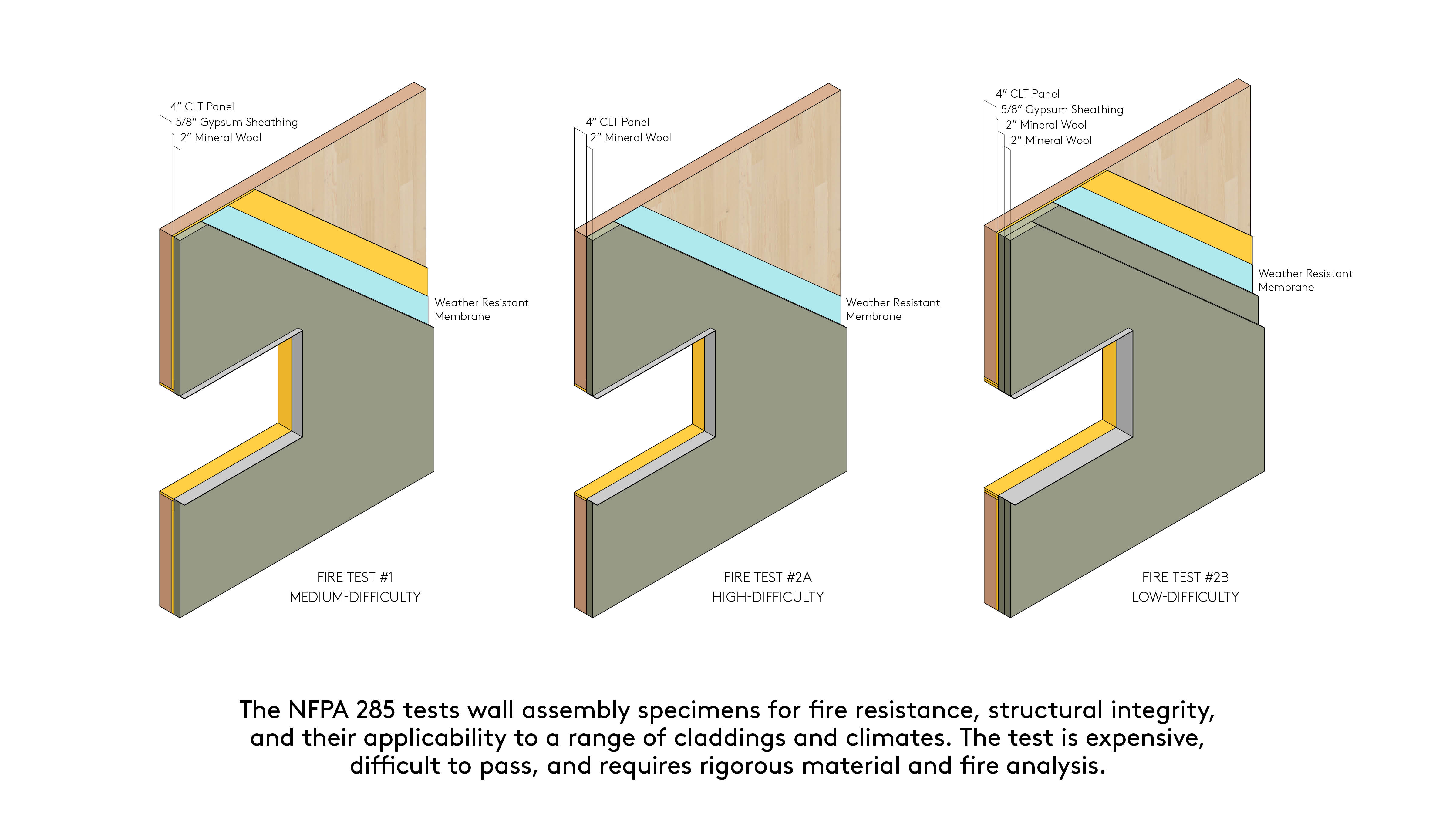

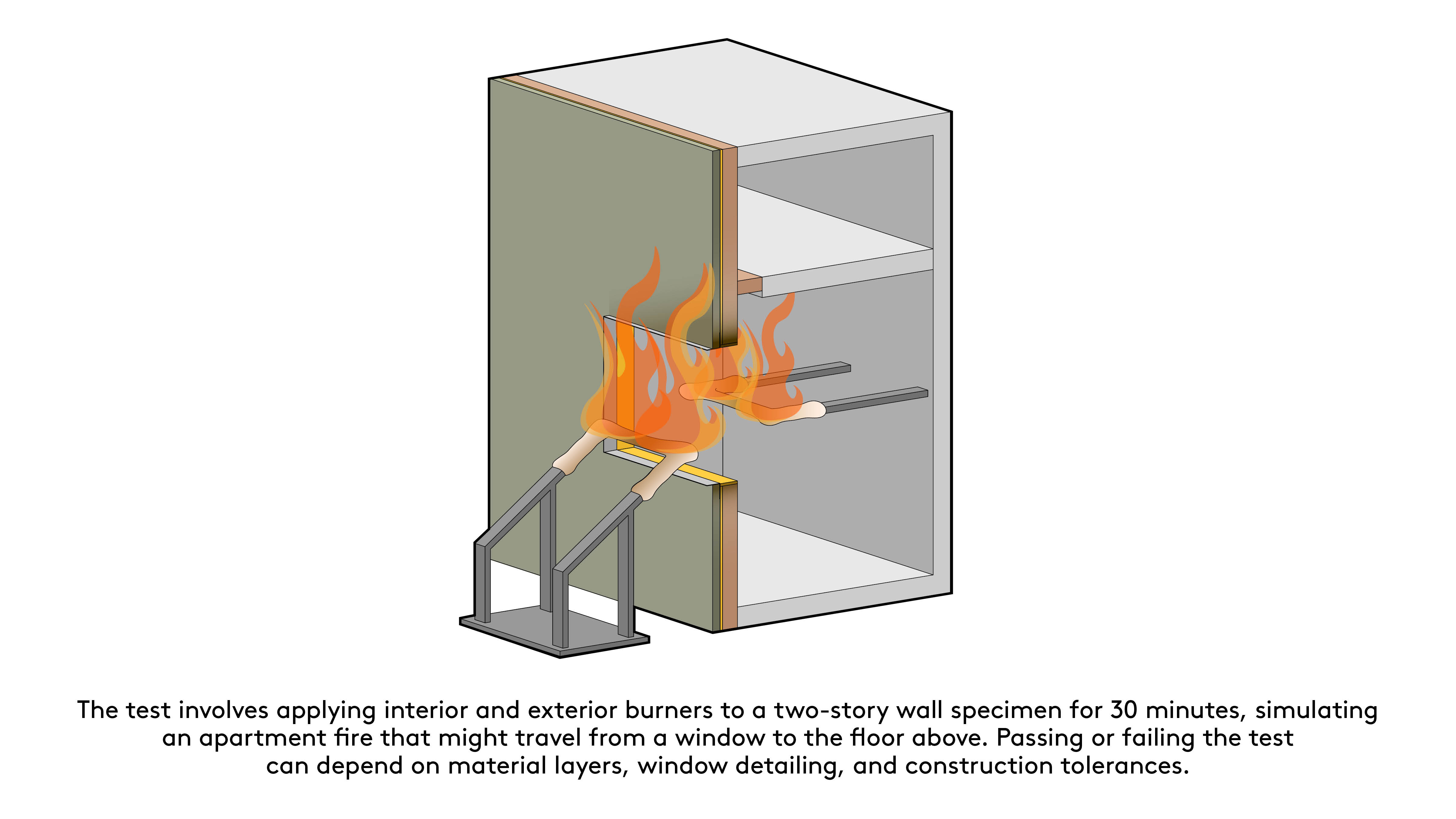

The 2021 International Building Code (IBC) includes provisions for mass timber construction up to 18 floors and 270 feet in height. Cross-laminated timber (CLT) is permitted to be used as part of an exterior wall assemblies in Type-IV construction, but the IBC contains a requirement that the exterior wall assembly pass the stringent National Fire Protection Association (NFPA) 285 “Standard Fire Test Method for Evaluation of Fire Propagation Characteristics of Exterior Wall Assemblies Containing Combustible Components” fire test. Without a relevant successful NFPA 285 fire test completed, a building project wanting to use CLT as a load-bearing, or non-load-bearing exterior wall over 40 feet in height could face a technical justification barrier and need to invest in an NFPA 285 fire test—adding significant project expense and risk.

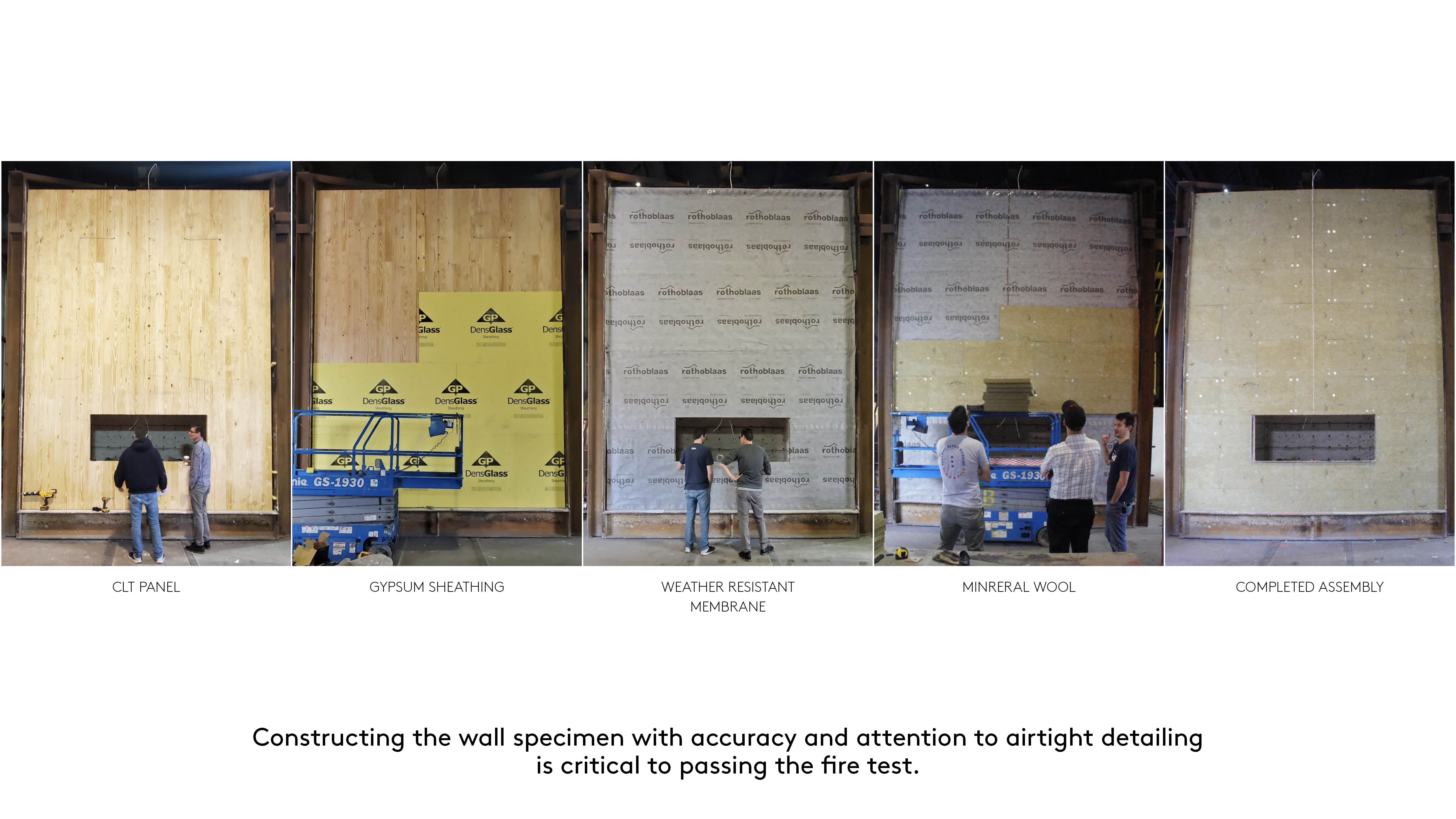

The team therefore looked to design an assembly for testing that would provide the most flexibility for future assembly designs, i.e. allowing for any non-combustible cladding material, while carrying a reasonable chance of passing the fire test.

Three assemblies were developed: a “middle-of-the-road” wall that was calculated to likely pass the NFPA 285 test; a “safe” version with extra gypsum and mineral wool protection that was almost guaranteed to pass, but would be a burden to future designers; and a “moonshot” test that would likely fail, but would be the least expensive to design with.

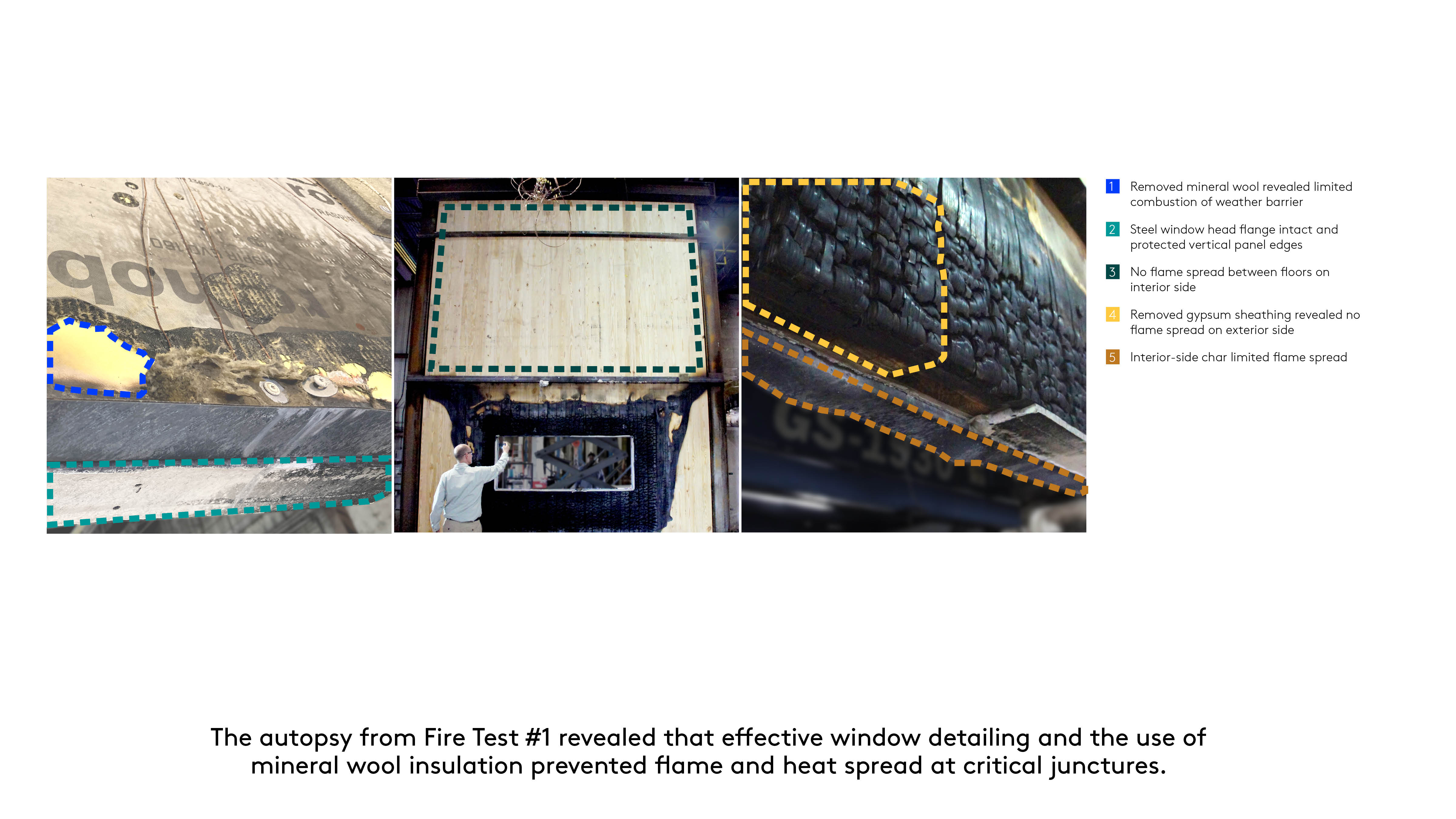

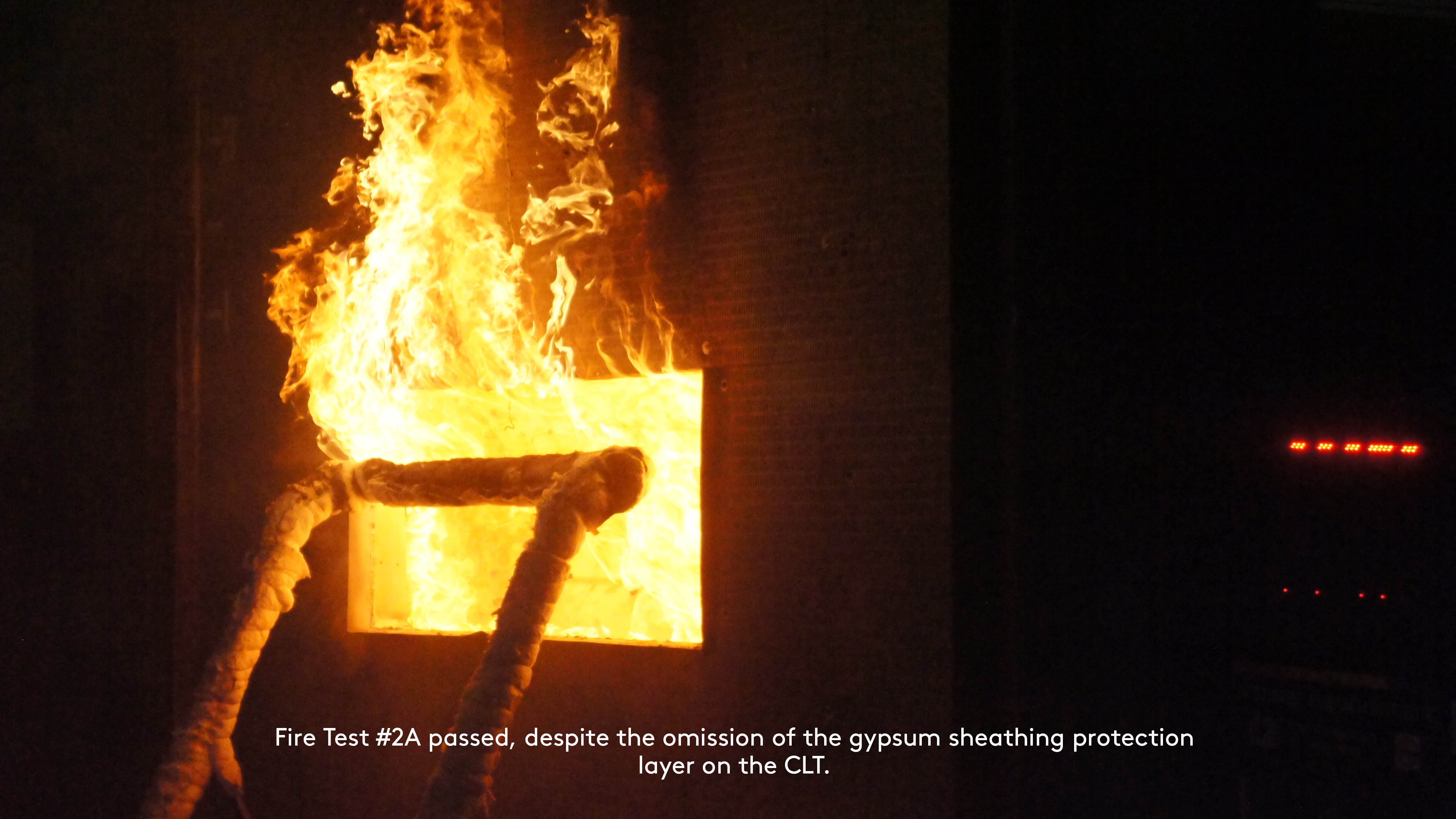

In spring 2022, contributing suppliers shipped materials to Southwest Research Institute in San Antonio, TX, and workers there constructed the specimen assemblies to the team’s specifications. The first 35-minute test on the “middle of the road” specimen passed with flying colors, due to strategic placement of mineral wool insulation and window protection. With success already in hand, team therefore decided to test the “moonshot” version the following week. This leaner design also passed, even without the requisite gypsum covering that’s prescriptively required by the IBC.

Looking Forward

Successfully testing two CLT wall assemblies to NFPA 285 standards opens new possibilities in mass-timber testing, construction techniques and materials, and future code provisions. As the first assemblies to pass NFPA 285 with mass-timber structure, they should invite attempts to test other mass-timber assemblies, with some new references points of what can pass. That’s especially true for assemblies with mineral wool and gypsum window protection, which performed very well in both tests. The ability to prefabricate exterior wall panels with CLT is now a possibility without running an expensive, project-specific NFPA 285 test. This would allow for new aesthetic and constructability criteria in projects, as well as potentially facades with reduced embodied carbon. Finally, by successfully testing the “moonshot” assembly, there is now hard evidence that the required gypsum layer on the exterior that the IBC currently requires may be removed in a future version of the code, further lowering the cost and time associated with mass timber construction.