Human Dimensions and Digital Tools

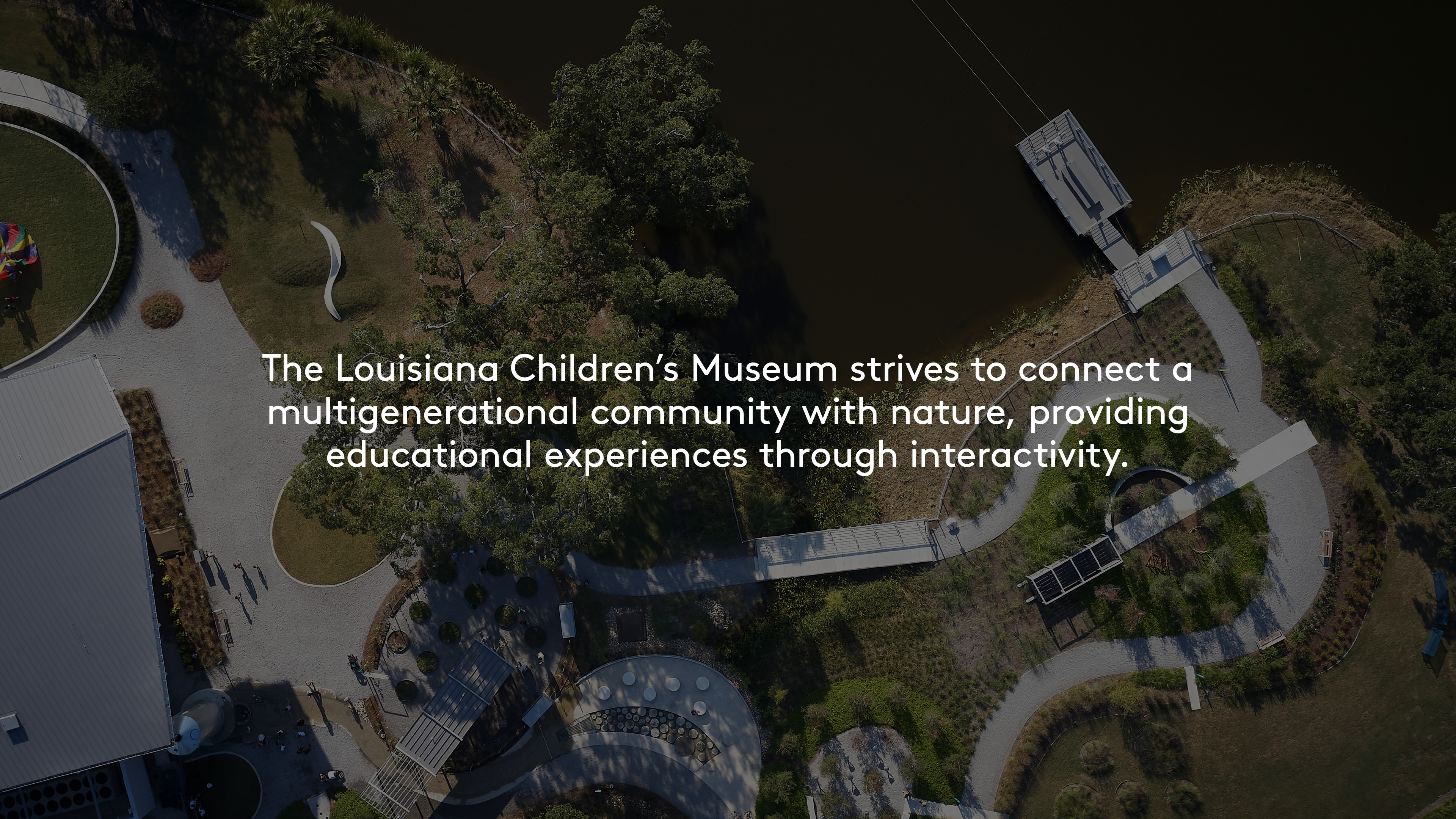

Vision

Anthropometry, the study of the human body's shape and proportion, can be recognized as one of architecture’s earliest tropes. Expanding on this tradition, this Mithun R+D effort investigates how the body can be embedded within contemporary design utilizing emergent digital fabrication tools.

Research

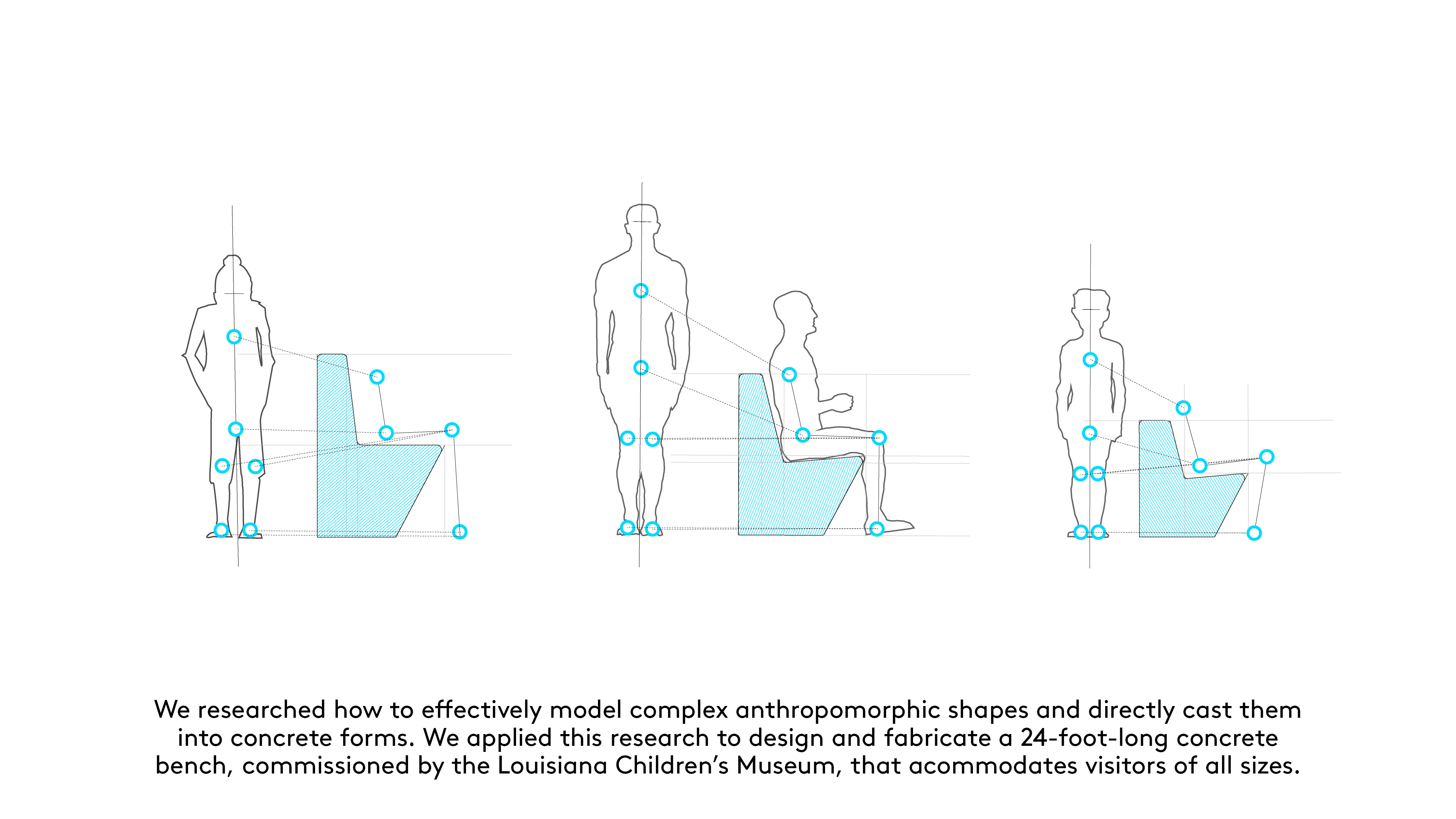

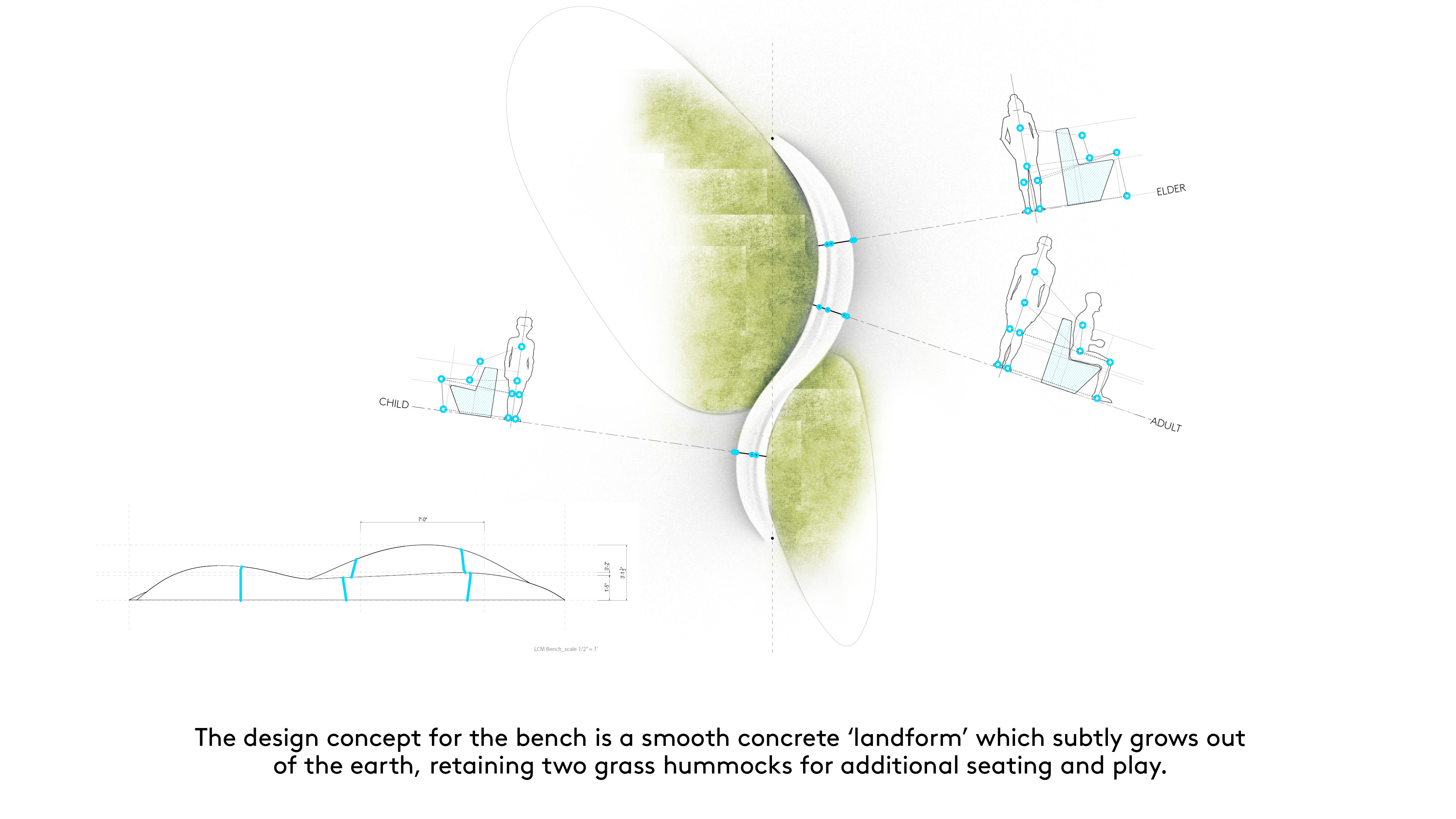

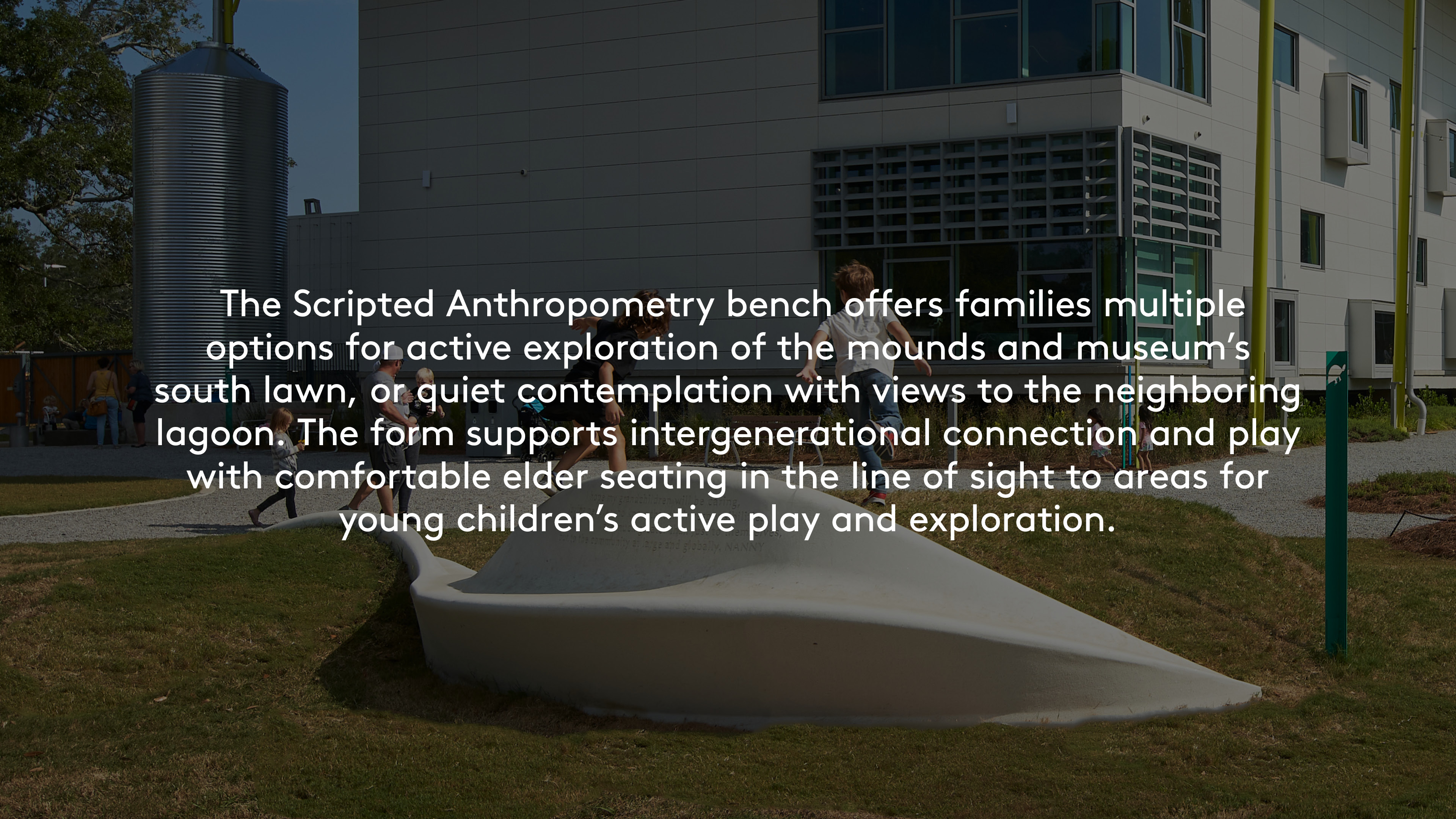

Using a combination of computer scripting and digital fabrication, the research focuses on how to effectively model complex anthropomorphic shapes and cast them into concrete. The topic was explored through design and fabrication of a 24-foot-long concrete bench commissioned by Louisiana Children's Museum (LCM).

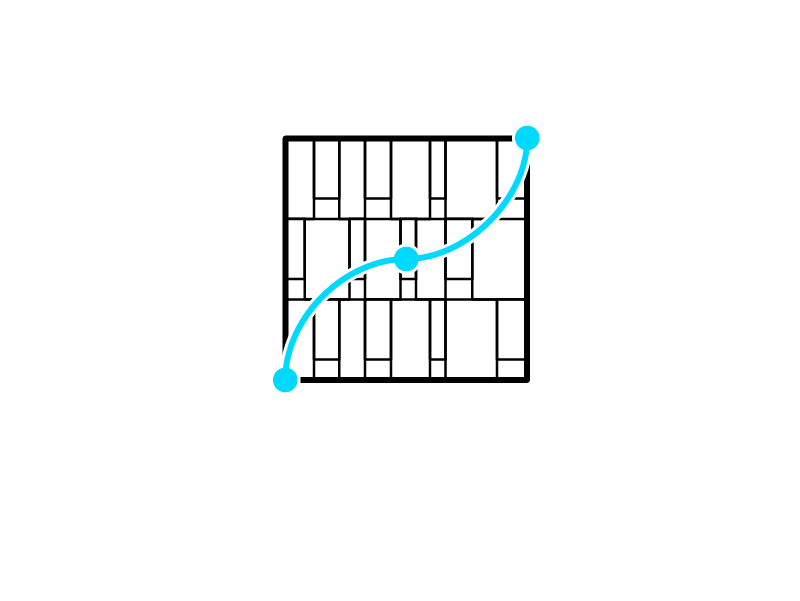

In recent years, computer scripting has become integral into the architectural design process to both automate tasks and rapidly generate forms through parametric modeling. For this project, the R+D team used scripting to quickly test and ‘digitally sculpt’ complex doubly-curved surfaces, a task often too cumbersome for traditional design tools. The team used human body dimensional data and ‘ideal’ ergonomic measurements to drive the form of the bench profile, including the backrest height, seat height, backrest angle, and seat width for various ages. The ideal geriatric seat profile for example, is roughly two and a half inches taller and two degrees more upright compared to the ergonomically ideal adult seat profile.

The ideal ergonomic profiles were used as the basis of a computer script which generated the final form of the bench—digitally interpolating these profiles over a 24-foot length. Unlike parametric scripts solely steered through numerical controls—which can be rigidly constrained and difficult to use—the team focused on creating a script which allowed for increased flexibility. Creating a feedback loop between NURBS-based control points and numeric parameters, the script allowed for a much more fluid control of the model. The control script was rewritten several times by the team, which found the simplicity and intuitiveness of the script had a significant effect on the final form of the bench being generated.

After a desired form was reached, physics engines were used to simulate rainwater drainage and refine the slope of the bench to mitigate puddling. Augmented reality tools and 3D printing were used to quickly visualize and test prototypes at varying scales. Using the digital model, a full-scale mock-up of the bench was wire-cut from foam and tested within the office.

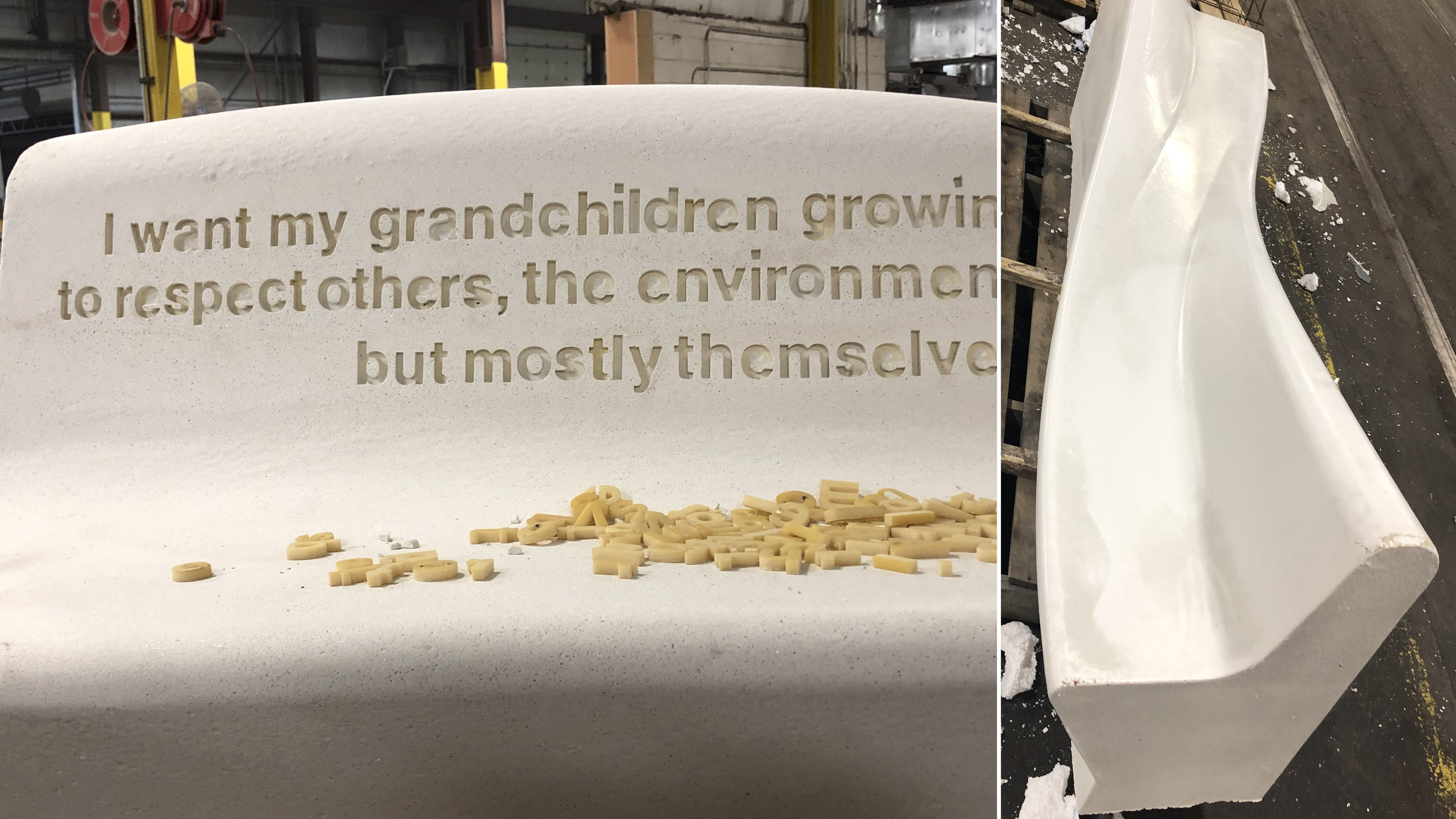

Following the R+D study, the Mithun team worked closely with Tectura design in Wausau, WI, to fabricate the bench. The fabrication team imported the 3D geometry produced from the script to generate tool paths for a 5-axis CNC. The bench forms were milled in four eight-foot sections—each cast weighing 1500-3500 lbs. Using milled polyurethane typeface, a quote from a past Louisiana Children’s Museum board member was cast into the backrest by adhering the letters to the inside of the foam mold.

Learn more about the design and fabrication of this bench in an ideas post, "Body Parametrics."

Looking Forward

This research team and others at Mithun continue to explore ways to harness scripting and parametric design as part of built projects and advanced studies. Opportunities abound to enhance the human experience through digitally tailored objects (like furniture, railings and building elements) and spaces (both interior and landscape). Mithun R+D welcomes opportunities to partner with fabricators to develop new systems and approaches that harness scripted geometry for diverse material applications.