Date Posted: 11.05.2021

In 1949, when Mithun was founded, atmospheric carbon dioxide (CO2) levels were at 311 ppm. Earlier this year the level hit 420 ppm, yet another record high, exceeding the ‘safe’ maximum levels of 350 ppm agreed upon in the scientific community. Even at the current 1.2°C global average warming some significant climate change impacts and consequences are now inevitable and irreversible. As just one example, the record-breaking June 2021 heat dome over the Pacific Northwest, peaking at 121°F in British Columbia, was determined to have been a once-in-a-millennium event. Within 30 years, with rising temperatures fueled by climate change, similar heat waves could become a once-in-a-decade or even once-every-five-years event.

The urgency of the climate crisis is clear.

Mithun has joined with other design, planning and construction leaders and built environment advocacy organizations as a signatory to the COP26 Communiqué, calling for world governments to establish climate action plans that will meet the 1.5°C maximum target from the 2015 Paris Accord. The time to act is now, with commitments that are brave and bold. The COP26 Communiqué vision calls for CO2 emission reductions of 65% by 2030 and to fully decarbonize by 2040 in order to have at least a 67% chance of not exceeding 1.5°C warming. The work of Mithun and the other signatories is demonstrating how low carbon design is achievable, showing the path forward needed to meet the targets in the COP26 Communiqué. With reductions of 50 to 65% required this decade, limiting all emissions starting now is vitally important.

WHY EMBODIED CARBON IS IMPORTANT

Embodied carbon is a component of building design and construction emissions that has been overshadowed by focus on energy efficiency. The Global Alliance for Building and Construction (GABC) and Architecture 2030 calculates the global embodied carbon emissions related to all building and infrastructure materials to be 23% of global CO2 emissions each year.

While energy efficiency, renewable energy and net zero have become commonly understood and gained significant traction, those strategies address only a portion of buildings’ total carbon impact. Operational energy, or operational carbon, is the energy and corresponding carbon emissions necessary to run a building. Embodied carbon, on the other hand, is the energy and corresponding carbon emissions necessary to make or construct a building.

The “time value” of atmospheric greenhouse gases (GHGs) like carbon dioxide and methane explain the growing sense of urgency around embodied carbon. Embodied carbon accounts for GHGs at the start of the building’s lifespan, which will remain in the atmosphere and affect the climate for decades before operational energy emissions reach and surpass the same levels. Architecture 2030 estimates that total carbon emissions from new construction between 2020 and 2040 will be 57% from embodied carbon and 43% from operational carbon. The upfront nature of embodied carbon means that a project team has one chance to minimize emissions when selecting construction materials.

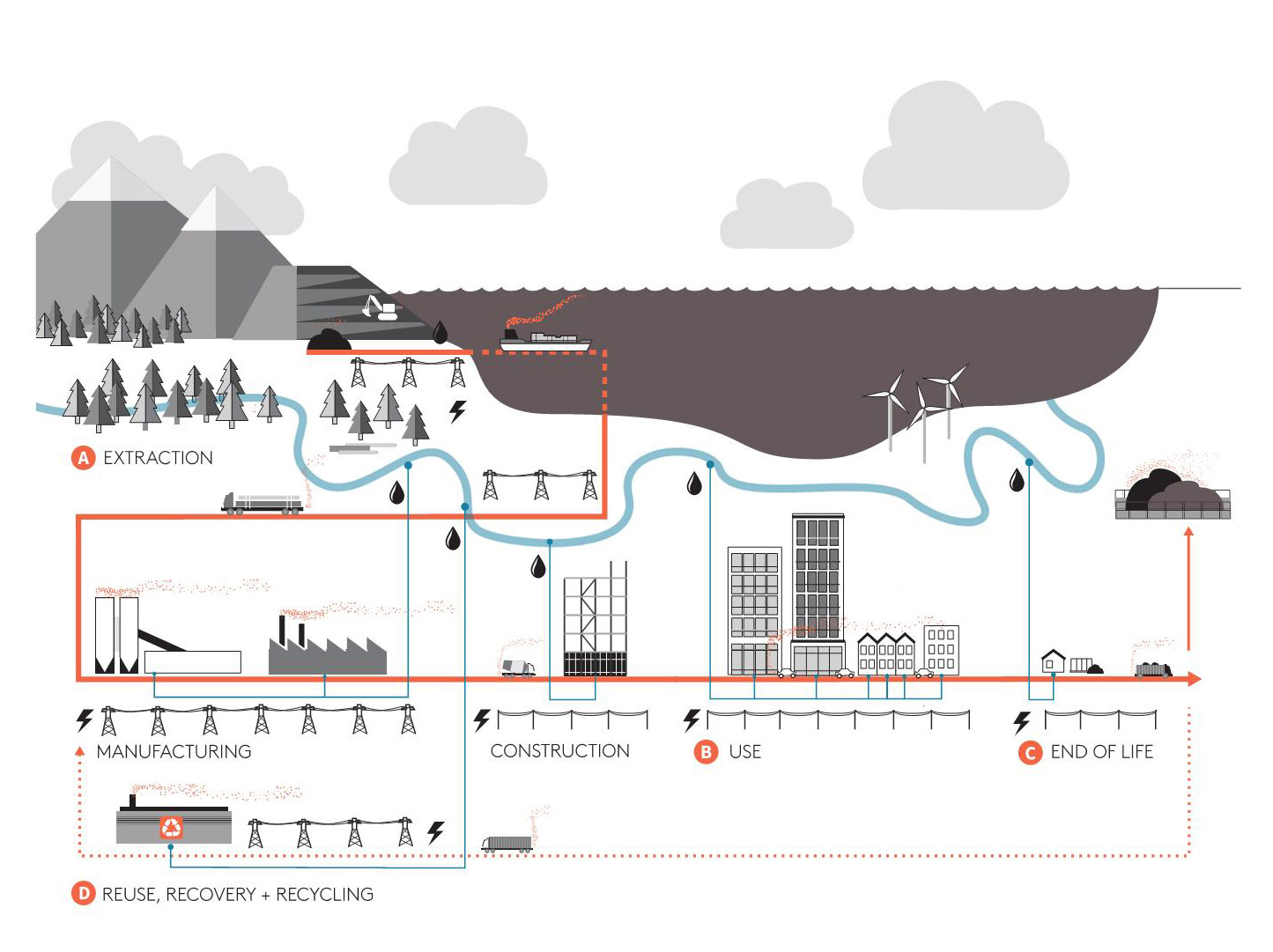

Life Cycle Assessment (LCA) tracks different environmental impacts of a building through a ‘cradle to grave’ analysis of each material. There are four primary stages in an LCA: (A) raw material extraction, manufacturing, and construction (including transportation), (B) use and maintenance, (C) end of life (demolition and disposal), and (D) beyond (reuse, recovery, and recycling).

2021, THE YEAR OF EMBODIED CARBON

For decades, Mithun has been recognized as a leader in sustainable design. In three of the past four years, our design portfolio has exceeded a 70% reduction in net operational energy use compared to a 2003 baseline. We created the publicly accessible Build Carbon Neutral calculator in 2007 and have offset all carbon emissions from our firm office operations since 2004. We can still do more.

Mithun framed 2021 as the Year of Embodied Carbon to reaffirm our commitment to low carbon buildings and communities, spark accelerated innovation internally and contribute decisively towards global efforts to limit atmospheric warming. It is not enough for one firm or the 60+ firms who signed on to the COP26 Communiqué to make this commitment. For this global effort to succeed at scale, we must all openly share our successes and setbacks with the hope that our process might serve as a replicable model, resource and inspiration to other organizations.

As part of the Year of Embodied Carbon, Mithun is taking these six actions:

01. LEARN CARBON BASICS

To achieve the overarching aim of increasing knowledge about embodied carbon, it was important to begin by building carbon literacy among design teams and with clients. Establishing fundamental concepts and vocabulary facilitates discussion and engagement at all stages of design, and provides a framework to retain and share information.

Achieving significant embodied carbon reductions requires cross-discipline collaboration and coordination. To equip design staff with the knowledge needed to prioritize low embodied carbon design strategies, Mithun programmed a series of events and trainings throughout the year on topics such as fundamentals of embodied carbon, incorporating Tally into BIM workflow and crafting specification language. Not only has this raised the level of understanding across our firm, it has also encouraged further engagement from interested staff—including building up our internal team of embodied carbon analysts—and prompted questions and ideas that further our design thinking around embodied carbon.

02. DESIGN FOR LOW CARBON

Building on our success with meeting energy use intensity (EUI) targets for Architecture 2030, every project team is setting a GWP target and benchmarking design against comparable project types. Just as we track project EUIs and assess performance across our design portfolio, we are developing a project GWP database to store the results of life cycle assessment (LCA) studies analyzing embodied carbon.

As we continue to learn how to design for a low embodied carbon footprint, this database enables us to identify trends across our portfolio and the best focus areas to target the most significant reductions in embodied carbon. Project teams—spanning architecture, landscape architecture and interior design—are becoming familiar with which construction materials are the largest contributors to GWP, and knowledgeable in evaluating emerging technologies and low carbon alternatives to mitigate embodied carbon impacts.

03. MEASURE OUR PROJECTS

Acknowledging that Mithun can advocate for decarbonization through our projects, we have been expanding LCA practice and its integration in our standard design workflow. We are learning to use and adapt LCA at various scales throughout design and across design disciplines to improve our buildings and test design options in real time.

Mithun has benchmarked more than 15 projects in design and construction over the past year that are below the maximum 500 kilograms carbon dioxide equivalent per square meter (kg CO2e/m2) emissions target set by the International Living Future Institute in its Zero Carbon certification. One-third of these projects have a GWP of less than 350 kg CO2e/m2. Designing to these low embodied carbon levels is a target for all Mithun projects. Below are summaries of these low-carbon projects, highlighting three unique approaches to mitigate embodied carbon.

The Bush School New Upper School / Seattle, WA

Floored by Mass Plywood Performance

Wood and other bio-based materials sequester carbon from the atmosphere over their growth cycles, resulting in net negative carbon emissions. This benefit is enhanced when wood is sourced from forests that are ecologically managed. Maximizing the use of mass timber provides opportunities to significantly reduce a project’s total carbon footprint, and even achieve zero embodied carbon.

At The Bush School, the owner, architect and contractor collaborated to find a structural solution that provided embodied carbon performance in parallel with conventional criteria such as constructability, schedule and overall cost. Shoebox LCA studies conducted early in design development showed the potential for mass timber construction systems—cross-laminated timber (CLT), dowel-laminated timber (DLT) and mass plywood—to reduce embodied carbon by more than 60% compared to a business-as-usual steel frame system.

Later in design development, the structural span requirements and floor-to-floor heights prompted a shift away from mass timber and back towards a steel frame system for constructability and structural efficiency. Having the earlier design option comparison in hand helped have an educated discussion about the merits of each system in meeting project goals. Ultimately, the project landed on a hybrid structure using wood, steel and concrete where each was most useful. The selected system combines a concrete basement level with light-gauge steel framing topped by two levels of mass plywood floor construction to reduce embodied carbon and optimize efficiency.

This hybrid approach served to both reduce embodied carbon and optimize structural efficiency. A final whole-building LCA showed about 50% savings in embodied carbon compared to the whole-building study conducted during design development. The final calculated GWP is 227 kg CO2e/m2, 425 metric tons CO2e.

In addition to pursuing ILFI’s Zero Energy certification, The Bush School is also on track to become the first Passive House certified and Salmon Safe certified school on the West Coast, achievements made possible by the project team’s commitment to integrated design and sustainability throughout the project.

Casa Adelante at 681 Florida / San Francisco, CA

Cementing Low Carbon Construction

Certain building typologies, site conditions or other project parameters can preclude the use of wood as a primary structural material. Concrete is a favorable building material for its durability, fire resistance and thermal mass, but is the most carbon-intensive material by standard design and manufacturing practices. In addition to encouraging the use of low carbon materials, we need to address the embodied emissions of high impact materials in our buildings.

Mithun’s mixed-use Casa Adelante at 681 Florida Street project—130 units of affordable housing in San Francisco’s Mission District—is a nine-story concrete building with multiple exposed concrete elements. Together with our client, the Tenderloin Neighborhood Development Corporation (TNDC), the project team focused on using LCA to benchmark GWP with the goal of assessing low-carbon strategies that also could be applied to TNDC’s future concrete projects.

Using whole-building LCA to benchmark embodied carbon in the structure, envelope and interior, we found the concrete structure comprised about 80% of total embodied carbon, meaning any significant reductions in embodied carbon would need to be achieved by mitigating the GWP of the concrete mixes. Engaging a team of experts, we joined the Bay Area Built Environment Embodied Emissions Project (BABEEEP) as a pilot project in the nation’s first embodied carbon concrete code, focusing on reducing the GWP of concrete mixes to low carbon concrete (LCC) limits through model code language and low carbon specifications.

The driver of both embodied carbon and cost in concrete is its structural requirements, including concrete mix variables such as aggregate amount and size, water-cement ratio, supplementary cementitious materials (SCMs), strength test age, and shrinkage limitation. The expanded project team focused on emerging paths to achieve lower concrete GWP, while also ensuring the subcontractors are given latitude to meet the embodied carbon goals of the concrete mixes. This process pushed back on structural assumptions, and ultimately made it easier for the concrete supplier to meet strength requirements. The result was both a cost reduction, and an estimated 36% reduction in embodied carbon. The final project GWP is estimated at 235 kg CO2e/m2, 3000 metric tons CO2e.

This collaborative effort helped both Mithun and TNDC understand not only the impact and feasibility of LCC design strategies, but also how to engage structural engineers and concrete suppliers to achieve significant embodied carbon reductions on other concrete projects. The knowledge learned at 681 Florida Street has already been applied to Mithun’s eight-story Balboa Park Upper Yard project. Collaborating with the structural engineer, contractor and concrete supplier, the team was able to reduce the concrete GWP by 59% compared to the NRMCA benchmark, per preliminary estimates of approved concrete mixes.

Balboa Park Upper Yard / San Francisco, CA

Innovating LCA Practice, Inside and Out

Typical LCA workflows on projects often exclude site and landscape scope and elements significant to interiors projects such as finishes, casework and furnishings. As part of our Year of Embodied Carbon, Mithun aimed to understand the embodied carbon impacts of all our design disciplines. In close collaboration with clients and peers, we have been at the forefront of developing LCA methods and applications for new building construction, as well as interiors, landscape and planning.

INTERIOR DESIGN

Consideration of the embodied carbon of interiors materials is often ignored in new construction projects in order to focus GWP mitigation efforts on more significant elements such as the building structure. However, as we mitigate the carbon embodied in a building’s structure through the use of mass timber and GWP limits on high-impact materials like concrete, commonly used finish materials such as nylon carpet, acoustic ceilings, and gypsum wall board become significant contributors to a project’s embodied carbon footprint.

To better understand the relative impacts of these materials—as well as casework and furnishings—Mithun has started the process of benchmarking our recent interiors work, focusing on tenant improvement (TI) projects. Developing a general roadmap for achieving embodied carbon in this scope of work is critical because the accelerated timelines common in TI projects can discourage the use of LCA in project design, and the embodied carbon impacts of TI scope of work aggregate over time with tenant turnover or refurbishment.

As part of this effort, we are evaluating product submittals and specifications for embodied carbon performance, understanding that embodied carbon reductions can be achieved at the product level by identifying manufacturers with low-carbon production practices. Building this practice is a key advocacy strategy, signaling a preference for material transparency and lower-carbon options to the wider industry. By working with our clients, we can often expand the breadth and scale of our decarbonization efforts, influencing client TI design standards and templates for future work.

Landscape Architecture and Site

To-date, the embodied carbon impacts of site design are largely unknown. Mithun’s landscape team is using project work as an opportunity to explore this blind spot, including embodied carbon as a performance metric alongside other site sustainability goals. We have started to evaluate embodied carbon and carbon sequestration potential of site materials by adapting building LCA tools and academic research, and using Pathfinder, the first online tool to focus on the carbon impacts of landscape design.

Embodied carbon also inspired design-thinking for a specific site element at the University of Oregon: the “stumpery” nurse log garden. Prompted by a discussion of the feasibility of upcycling existing landscape items slated for removal, the team has harvested fallen trees from campus, selectively removed trees from the site for reuse as nurse logs, and drafted unique specification sections and nurse log details for construction documents.

Additional active projects that are leading the way with GWP below 350 kg CO2e/m2:

04. OFFSET our office OPERATIONS

For more than 17 years, Mithun has engaged in annual carbon accounting for our office operations Scope 1 and Scope 2 emissions, as well as Scope 3 emissions related to work-related travel by air and car, achieving carbon neutrality with the purchase of carbon offsets. Initially in 2004 we chose a market-driven audit and offset program, becoming an Associate Member of the Chicago Climate Exchange.

Since 2011 Mithun has been a member of The Climate Registry (TCR), a non-profit organization governed by U.S. states and Canadian provinces and territories. TCR offers voluntary and compliance GHG reporting programs globally, and annually updates their reporting protocols. After completing our annual count, we contract with an independent auditor whose work is verified by TCR and we offset those carbon emissions on the carbon market. The total office emissions per employee have decreased every year since 2014. Our consistent reporting efforts have received TCR Gold status.

05. CREATE A LOW-CARBON CULTURE

Converting knowledge into firm culture may be the biggest step. As an integrated design firm, we are working to integrate embodied carbon into all areas of our practice, spanning architecture, landscape architecture, interior design, urban design and planning. Reinforcing the importance of carbon throughout project management and workflow requires ongoing communication and facilitation. Some specific angles we have found useful are strong messaging from firm leadership, engagement with project teams early and often, and continually working to incorporate lessons learned into our next projects.

Our communication efforts seek out new and innovative ways to communicate and reinforce embodied carbon messaging. In 2018 we instituted a segment at monthly staff meetings called Sustainability Snack with a five-minute overview of an important sustainable design topic. This year, key Snacks addressed low-embodied-carbon materials, tips to specify and select low GWP products, and project success stories featuring teams that reduced embodied carbon below 350 kg CO2e/m2.

An internally created three-part education series on embodied carbon was offered to the entire office and recorded for future reference. Topics included embodied carbon 101, incorporating whole-building LCA into the design process, and a review of embodied carbon trends across Mithun projects.

To round out the year, a friendly carbon competition was held to find within our active projects the lowest embodied carbon champion in the categories of exterior wall assembly, interior material(s) and site tree planting condition.

As part of the firm’s robust internal research and development program, Mithun R+D, we began a deep dive into embodied carbon in 2017 with research titled Embodying Change: Engaging Carbon Workflows. This effort studied the application of LCA software and methods to our design workflows across multiple scales and project types. The Embodying Change team ran a range of analyses, from whole-building LCA to individual material comparisons, documenting best practices for seamless integration of embodied carbon accounting into the firm’s design process. The effort gave us a running head start into our Year of Embodied Carbon.

Another recent R+D project is Build Carbon Neutral 2.0: Enhanced Tool for Carbon Calculation, updating Mithun’s buildcarbonneutral.org (BCN) calculator, a publicly available and widely referenced tool for early estimation of a project’s embodied carbon impacts. Developed in partnership with the Lady Bird Johnson Wildflower Center at the University of Texas at Austin and launched in 2007, the BCN calculator is currently being updated with support from an AIA Upjohn Grant to incorporate the past 15 years of lessons learned at Mithun and across the broader industry to better address complex construction types, specific structural quantities, site design and above-ground biomass for simplified carbon assessments.

06. ADVOCATE FOR DECARBONIZATION

Mithun has been a longtime leader in the advocacy and advancement of sustainable design; our involvement with low carbon initiatives in recent years is a continuation of that leadership. In addition to signing on to the COP26 Communiqué, our team also invested incredible effort in activities including collaborating with peer architecture, engineering and construction industry leaders; presenting research at conferences; participating on regulatory panels to advance building codes; serving on working groups with allied organizations and more.

Mithun project teams are actively sharing our embodied carbon work and findings in various channels: through collaboration with other design firms on Mithun R+D efforts and the Carbon Leadership Forum, in presentations at conferences including Greenbuild and the Net Zero Conference, and via our online, open-source BCN embodied carbon calculator.

Mithun provides volunteer time for staff to participate in important publications such as the Building Decarbonization Practice Guide, and to serve on panel or task force positions for the Washington state energy code Technical Advisory Group, Mayoral Zero Emission Buildings Taskforce for the City of San Francisco, and Building Decarbonization Taskforce with SPUR. There are many ways to get involved and support the work of decarbonization at local, regional and national levels.

AFTER A YEAR OF EMBODIED CARBON, WHAT’S NEXT?

This year-long focus on embodied carbon is a starting step. The effort does not end at the close of the year, but will serve as the foundation for a continuous path of improvement. While our goal to know the embodied carbon on every project fell short, the projects we did model yielded embodied carbon reduction benefits and supplied a wealth of knowledge that will be directly applicable to future projects. Lessons learned over the past year will continue to work their way into specification updates and the materials we keep in our library. Momentum is building.

Mithun invites firms and organizations around the world to join us, to take similar steps and establish calendar year 2022 as your own Year of Embodied Carbon. The steps and suggestions here are examples of measures that can be implemented in your own practice. In joining together, our collective actions will significantly reduce the emissions from embodied carbon each year, making the 2030 and 2040 target goals in the COP26 Communiqué achievable.